Plate Heat Exchanger (PHE)

25000.00 - 350000.00 आईएनआर/टुकड़ा

उत्पाद विवरण:

- मोटाई Plate thickness typically 0.5 mm

- मैक्स। क्षमता Up to 60 m³/h

- अधिकतम दबाव 1.6 MPa (16 bar)

- पाइप की संख्या Depends on configuration, typically 2 (inlet & outlet)

- एयर वॉल्यूम N/A (used for liquid-to-liquid heat exchange)

- तापमान

- व्यास Inlet/Outlet Connection: DN32 - DN100

- Click to view more

X

प्लेट हीट एक्सचेंजर (PHE) मूल्य और मात्रा

- 1

- टुकड़ा/टुकड़े

- टुकड़ा/टुकड़े

प्लेट हीट एक्सचेंजर (PHE) उत्पाद की विशेषताएं

- N/A (Non-electric equipment)

- Up to 1.6 MPa

- Approximately 55 kg

- Plate thickness typically 0.5 mm

- Length: 650 mm, Width: 300 mm, Height: 900 mm (varies by configuration)

- 10 - 50 m³/h (based on model and plate area)

- Up to 60 m³/h

- Depends on configuration, typically 2 (inlet & outlet)

- N/A (used for liquid-to-liquid heat exchange)

- 1.6 MPa (16 bar)

- N/A (Non-electric equipment)

- Inlet/Outlet Connection: DN32 - DN100

प्लेट हीट एक्सचेंजर (PHE) व्यापार सूचना

- एन/ए

- 50 प्रति महीने

- 5-6 हफ़्ता

- ऑल इंडिया

उत्पाद विवरण

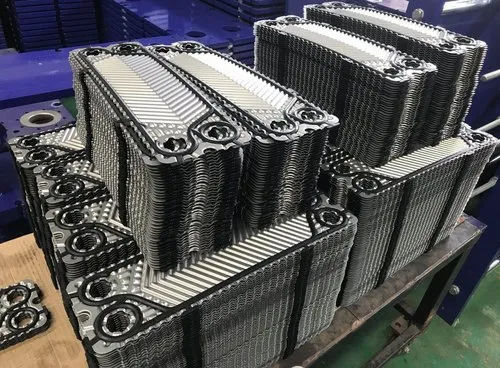

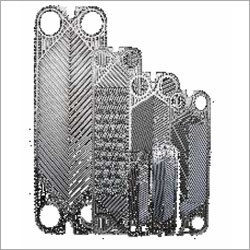

Discover the matchless performance of our Plate Heat Exchanger (PHE), engineered with superb Stainless Steel 304/316 plates and a robust Carbon Steel Frame. This special equipment delivers an unbeatable heat transfer area, from 0.5 up to 100 m, tailored by the number of plates (10150). Gasket material (EPDM/NBR/Viton) is selected for optimum application, ensuring reliability in HVAC, chemical, and pharmaceutical industries. Featuring scarce availability and a bargain value, its blue-coated frame, easy maintenance, and flexible connection types make it the preferred choice for exporters, importers, suppliers, and traders across India.

Advanced Features and Versatile Applications

The Plate Heat Exchanger (PHE) offers superb efficiency through its gasketed, frame and plate structure. Featuring Stainless Steel plates and selectable gasket materials, it promises durability and adaptability. It excels in liquid-to-liquid heat transfer for HVAC, food processing, power plants, and pharmaceuticals. Maintenance is matchless, with easy disassembly for cleaning and inspection. Application methods are straightforward, and its usage is specific to high-pressure, temperature-controlled environments, ensuring reliable heating and cooling across industries.

FOB Port, Quick Sample Policy, and Premium Certifications

Our Plate Heat Exchanger is available for export from major Indian ports, ensuring swift transport services and express shipping worldwide. We offer a transparent sample policy allowing clients to assess quality conveniently. Certified under premium standards such as GB150 and ASME, each unit guarantees uncompromised performance and safety. With extensive logistics support, receiving your order quickly and securely is assured, giving you confidence in every transaction and installation.

Advanced Features and Versatile Applications

The Plate Heat Exchanger (PHE) offers superb efficiency through its gasketed, frame and plate structure. Featuring Stainless Steel plates and selectable gasket materials, it promises durability and adaptability. It excels in liquid-to-liquid heat transfer for HVAC, food processing, power plants, and pharmaceuticals. Maintenance is matchless, with easy disassembly for cleaning and inspection. Application methods are straightforward, and its usage is specific to high-pressure, temperature-controlled environments, ensuring reliable heating and cooling across industries.

FOB Port, Quick Sample Policy, and Premium Certifications

Our Plate Heat Exchanger is available for export from major Indian ports, ensuring swift transport services and express shipping worldwide. We offer a transparent sample policy allowing clients to assess quality conveniently. Certified under premium standards such as GB150 and ASME, each unit guarantees uncompromised performance and safety. With extensive logistics support, receiving your order quickly and securely is assured, giving you confidence in every transaction and installation.

FAQs of Plate Heat Exchanger (PHE):

Q: How does the Plate Heat Exchanger (PHE) function in different industrial applications?

A: The PHE transfers heat between liquids through stainless steel plates, efficiently supporting processes in HVAC, food processing, chemicals, and pharmaceuticals. Its flexible plate and gasket options make it suitable for diverse operating environments.Q: What materials are used in the construction of your Plate Heat Exchanger?

A: Our PHE features Stainless Steel 304/316 plates for corrosion resistance, a Carbon Steel frame for structural strength, and gasket materials like EPDM, NBR, or Viton chosen according to application requirements.Q: When is regular maintenance recommended for optimum performance?

A: Regular inspection and cleaning are advised every six months, or following intensive operational cycles, to maintain superb efficiency and prevent any fouling or gasket wear.Q: Where can the Plate Heat Exchanger be installed?

A: Our PHE is designed for installation in varied settings, including HVAC plants, chemical and food processing facilities, pharmaceutical units, and power stationsanywhere efficient heat transfer is required.Q: What is involved in the process of maintenance and cleaning?

A: Maintenance entails easy disassembly of the frame, removal of individual plates for cleaning or gasket replacement, and simple reassemblystreamlining uptime and reducing operational disruptions.Q: How can buyers benefit from your sample policy and certifications?

A: Clients gain assurance of quality through our sample evaluation process and premium certifications (GB150, ASME) that guarantee adherence to international standards, fostering trust and long-term reliability.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

प्लेट हीट एक्सचेंजर्स (पीएचई प्लेट्स) अन्य उत्पाद

Back to top

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें