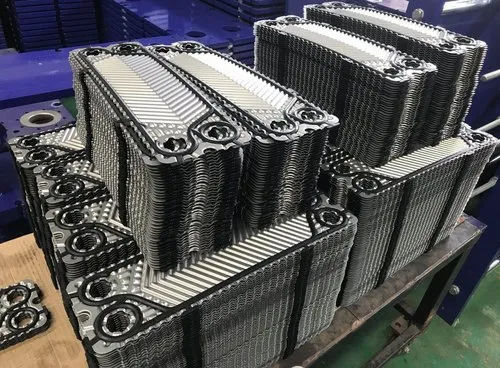

Plate Heat Exchanger Repair And Services (PHE Refurbishment)

1000 INR/Piece

Product Details:

- Diameter Plate width up to 1.5 meters (varies with plate model)

- Number of Pipe Dependent on PHE unit, typically 24 connections

- Thickness Plate thickness 0.5 mm to 1 mm (model dependent)

- Max Pressure Up to 25 bar depending on model

- Air Volume Not applicable (liquid media system)

- Max. Capacity Model-dependent, generally up to 1,000,000 Kcal/hr or more

- Temperature Up to 180C operating temperature after refurbishment

- Click to view more

X

Plate Heat Exchanger Repair And Services (PHE Refurbishment) Price And Quantity

- 100 Piece

- 1000 INR/Piece

- On-site or off-site refurbishment options

- Hydrostatic and pneumatic leak testing performed after re-assembly

- Upgrade of plates/gaskets available upon request

- Typically 37 days depending on job scope and PHE size

- For all major plate heat exchanger brands and models

- Full disassembly, cleaning, re-gasketing, re-assembly, performance testing

- Chemical descaling, mechanical brushing, high-pressure jetting

- All work in accordance with ISO 9001 and manufacturer standards

- Replacement with OEM or high-quality equivalent gaskets

- Plates: Stainless Steel, Titanium, SMO, Hastelloy; Gaskets: NBR, EPDM, Viton

Plate Heat Exchanger Repair And Services (PHE Refurbishment) Product Specifications

- Up to 25 bar, depending on PHE model

- Depends on service tools used, standard 220V/380V for machinery

- Not applicable for manual repairs; servicing tools may require electric/pneumatic power

- Plate thickness 0.5 mm to 1 mm (model dependent)

- Up to 180C operating temperature after refurbishment

- Dependent on PHE unit, typically 24 connections

- Up to 25 bar depending on model

- Client-specific, up to 460 m/h (model dependent)

- Refurbished to original or improved condition

- Not applicable (liquid media system)

- Plate width up to 1.5 meters (varies with plate model)

- Stainless Steel / Titanium / SMO / Customized as per original PHE

- Model-dependent, generally up to 1,000,000 Kcal/hr or more

- Custom based on plate size and number; service adaptable to all sizes

- Depends on PHE model and plate count, typically ranges from 50 kg and above

- On-site or off-site refurbishment options

- Hydrostatic and pneumatic leak testing performed after re-assembly

- Upgrade of plates/gaskets available upon request

- Typically 37 days depending on job scope and PHE size

- For all major plate heat exchanger brands and models

- Full disassembly, cleaning, re-gasketing, re-assembly, performance testing

- Chemical descaling, mechanical brushing, high-pressure jetting

- All work in accordance with ISO 9001 and manufacturer standards

- Replacement with OEM or high-quality equivalent gaskets

- Plates: Stainless Steel, Titanium, SMO, Hastelloy; Gaskets: NBR, EPDM, Viton

Plate Heat Exchanger Repair And Services (PHE Refurbishment) Trade Information

- VADODARA

- 100000 Piece Per Month

- 10 Days

- STANDARD

- All India

Product Description

We are Providing all The Type of PHE Refurbishment like ( Alfa Laval,Sondex,Tranter,Kelvion,APV,Funke,IDMC)

We will Provide Best Quality Of Refurbishment services in pan India

Comprehensive Plate Heat Exchanger Refurbishment

Our service dismantles, cleans, and rebuilds plate heat exchangers, using state-of-the-art chemical descaling, brushing, and high-pressure jetting. Gasket replacement is carried out with either OEM or high-grade alternatives. We cater to all major brands and sizes, offering tailored upgrades and repairs for your specific requirements.

Expert Handling of Materials and Gaskets

We service a range of plate materials including Stainless Steel, Titanium, SMO, and Hastelloy, and work with leading gasket types such as NBR, EPDM, and Viton. This ensures compatibility with operating conditions up to 180C and 25 bar, optimizing both durability and efficiency.

Performance Testing and Compliance Assurance

Each refurbishment includes thorough hydrostatic and pneumatic leakage tests post-assembly, guaranteeing reliability and safety. Services comply with ISO 9001 as well as manufacturer specifications, ensuring consistent, high-standard results for every project.

FAQ's of Plate Heat Exchanger Repair And Services (PHE Refurbishment):

Q: How is my plate heat exchanger refurbished?

A: Plate heat exchanger refurbishment involves complete disassembly, chemical and mechanical cleaning of the plates, followed by replacement of worn gaskets. The unit is then carefully reassembled and subjected to hydrostatic and pneumatic leak tests to verify integrity before delivery.Q: What plate and gasket materials do you handle during servicing?

A: We work with plates made from Stainless Steel, Titanium, SMO, and Hastelloy, and replace gaskets with NBR, EPDM, and Viton, ensuring suitability for varied operational environments and high-performance standards.Q: When can I expect my PHE repair or refurbishment to be finished?

A: Turnaround time for standard refurbishment is typically 3-7 days, based on the scope and size of your unit. Expedited or customized services may vary depending on specific project requirements.Q: Where are your refurbishment services available?

A: Services are extended both on-site and off-site, allowing flexibility whether your heat exchanger is operational in the field or can be transported to our facility. Coverage is available across India for exporters, importers, suppliers, and traders.Q: What is involved in your plate cleaning process?

A: We utilize chemical descaling, mechanical brushing, and high-pressure jetting to thoroughly clean each plate. These methods effectively remove scale, sediment, and contaminants, restoring efficient heat transfer performance.Q: How do you ensure the refurbished heat exchanger meets operational standards?

A: All refurbishments adhere to ISO 9001 and manufacturer guidelines. Units undergo rigorous pressure and leak testing, ensuring reliable operation at specified temperatures, pressures, and flow rates post-service.Q: What benefits do refurbished plate heat exchangers provide?

A: Refurbished plate heat exchangers offer restored or enhanced efficiency, longevity, and reliability. Upgrades of plates or gaskets are also available upon request, helping reduce downtime and extend asset life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plate Heat Exchangers ( PHE Plates )' category

Back to top